Motorcycle Parts New Zealand Specialists Can Be Fun For Everyone

Table of ContentsIndicators on Motorcycle Parts New Zealand Specialists You Need To KnowMotorcycle Parts New Zealand Specialists Fundamentals ExplainedMotorcycle Parts New Zealand Specialists Fundamentals ExplainedMotorcycle Parts New Zealand Specialists - The FactsThe Best Guide To Motorcycle Parts New Zealand SpecialistsGetting The Motorcycle Parts New Zealand Specialists To WorkMotorcycle Parts New Zealand Specialists for DummiesThe Buzz on Motorcycle Parts New Zealand Specialists

Reach out to one of our professionals today.CNC machining innovation is quickly coming to be the focal factor of various manufacturing processes around the world as a direct outcome of its lots of benefits over various other approaches. Furthermore, the industries that make bikes have actually hopped on board with this pattern. One of the most ingenious business are currently developing their engine elements and wheels making use of machining strategies initially established for motorcycle parts.

On the other hand, the impacts of sector are the primary emphasis of this article. Let's obtain right into it. You may be asking yourself why we make use of. It is not difficult to fathom the aspects that resulted in this result. Since we have your interest let us clarify the reasoning behind this modern-day development in the motorcycle manufacturing market.

The Best Guide To Motorcycle Parts New Zealand Specialists

On top of that, you have full control over the appearance of the parts, also to the minute details. Periodically, motorcyclists may choose to fix up their adventure by setting up aftermarket components or modifying the bike's makeover. Once more, computer mathematical control (CNC) machining is one of the most functional technique. Upgrades may be of any type of type and style you desire.

Motorcycle Parts New Zealand Specialists for Beginners

CNC machining might be made use of to make almost all of a motorcycle's steel and plastic parts. To proceed, we'll review numerous machined components for bikes.

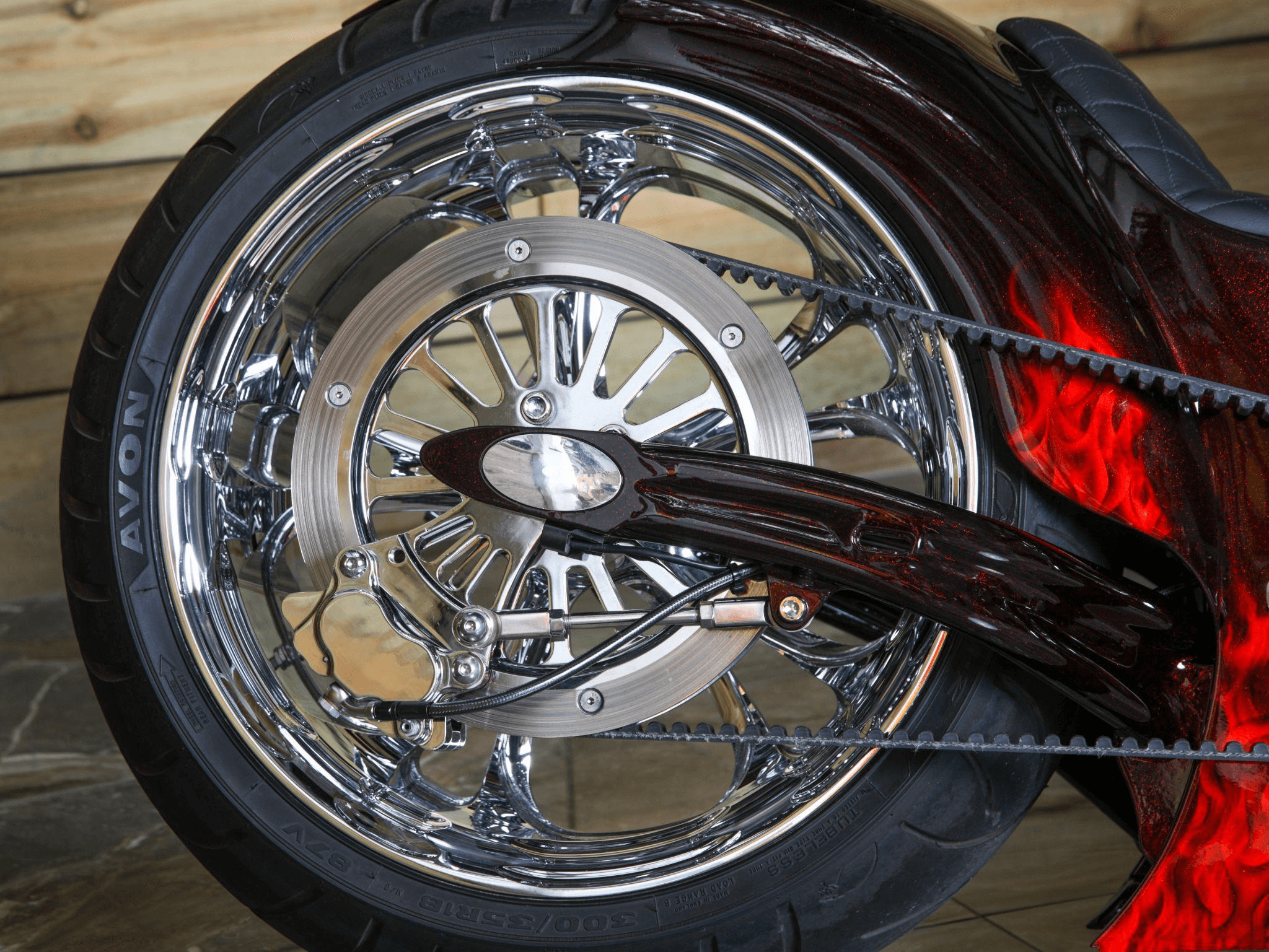

When personalizing the wheels, the disks are where the focus should be. The bulk of them are constructed of aluminum. Aluminum alloys are popular for the outstanding machining capabilities that they possess. Milling treatments are used to acquire the desired level of wheel modification. An additional facet of the bike that might be customized is the tires.

8 Simple Techniques For Motorcycle Parts New Zealand Specialists

When it concerns a lorry (or a motorbike), one of the most important part is the engine. Several people mention it as the "heart" of the car. On the various other hand, the camshaft, the cylinder head, and the pistons have a tendency to be detailed and need layouts with a high degree of precision.

Usage just high-quality products, nonetheless, considering that these lights are crucial for the safety of motorcyclists and other chauffeurs or individuals on the roadway, particularly at evening. Bike fronts lights have 3 primary components: the light bulb, or light resource, the lens, and the real estate.

Milling procedures with a perfect surface would certainly result in the lenses having a reflective high quality that resembles that of a mirror. The cover, on the various other hand, is not made up of vulnerable products; additional resources instead, it is built out of challenging polymers that can be machined right into even more complex patterns.

Motorcycle Parts New Zealand Specialists for Beginners

They usually have intricate geometries with a wealth of min details. Bike makers frequently cast these elements, however just for the production of bespoke parts. Nonetheless, CNC machining is the approach of choice when generating special pieces. Machining on five axes in today's world is the means through which any type of layout form might be realized.

The success of the procedure is contingent on the mill cutters' capability to compute subtle and challenging angles accurately. Select Runsom for your tailored motorcycle components! We have the capability to produce challenging and trendy components making your motorcycle matchless. Most are crafted from light weight aluminum or steel alloys, each of which has its usages and advantages.

Below are a couple of examples of metals commonly made use of in motorcycle component machining. Light weight aluminum is the key product utilized by business specializing in creating customized motorcycle components to develop many of these components - Motorcycle Parts New Zealand Specialists.

Zinc refers to another steel that is really light click here to read in weight and has wonderful machining top qualities as a result of its high mechanical stamina. This material might be created into practically like it any form and preserves its dimensions well. Also mission-critical parts that need a high degree of accuracy may gain from their use.

Fascination About Motorcycle Parts New Zealand Specialists

An additional steel that sees heavy usage in the production of CNC-customized elements is magnesium. It is amongst the lightest steels that are now obtainable and has excellent machinability functions and stamina proportionate with its reduced weight. One of the drawbacks of magnesium is that its dust may quickly ignite.

As a result of its superior machinability and weldability, stainless steel is an alloy that is especially appropriate for CNC procedures. Along with this, they have great corrosion resistance and a high visual charm. Their most common usage in producing various motorcycle elements is bolts, such as screws and screws. Their low sensitivity to oxidation and corrosion makes them perfect for this use.

Some Known Facts About Motorcycle Parts New Zealand Specialists.

It appears that CNC turning and grating are the foundational procedures. Alternative strategies exist, such as drilling. Allow's examine a lot of these machining methods comprehensive. The CNC transforming technique is considered a subtractive manufacturing method. On top of that, it calls for keeping bars of product, most usually plastic or metal, in placement and after that turning a cutting tool to remove sections of the material as the product is turned.

These techniques are just as important and produce elements with high precision and regular top quality. They are respectively: grinding, laser cutting, and drilling. The term "surface finish" refers to post-processes after the initial machining stage. Motorcycle Parts New Zealand Specialists. The processes assist boost the total top quality of the machined motorcycle components. Below are the brief introduction, pros and cons of five surface treatment methods.

Facts About Motorcycle Parts New Zealand Specialists Revealed